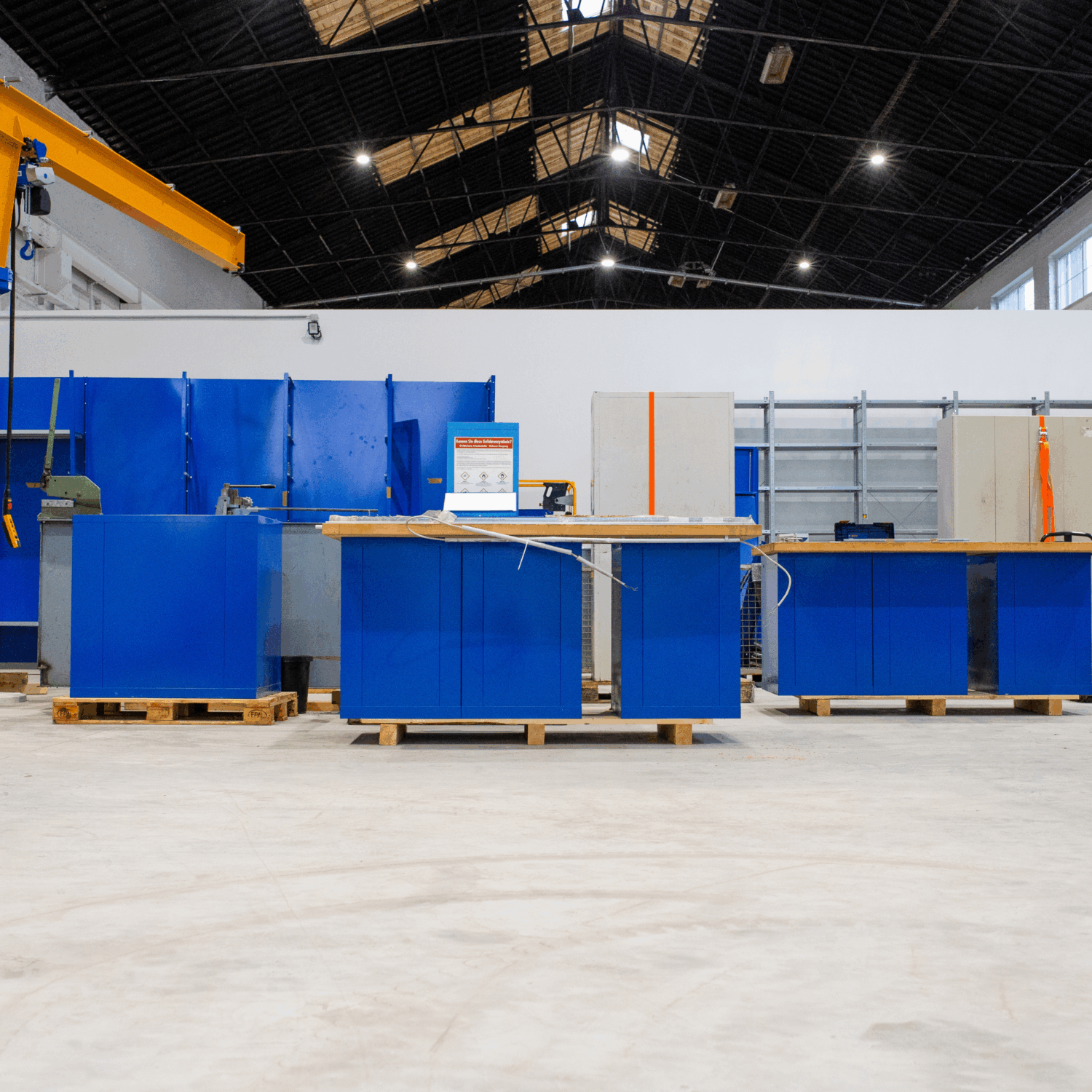

Warehouse removals with ZBV Fels: safe, fast and professional

Für viele Unternehmen ist das Lager ein zentraler Bestandteil der Wertschöpfung – hier lagern nicht nur Waren, sondern auch betriebsrelevante Abläufe. Umso wichtiger ist es, dass Lagerumzüge sorgfältig geplant wird, denn Ausfallzeiten, Lieferverzögerungen oder Engpässe dürfen nicht entstehen.

The requirements increase further if the warehouse relocation has to take place parallel to ongoing operations. Precise and forward-looking planning is therefore essential to ensure a smooth and successful process.

There are numerous degrees of complexity involved in a warehouse relocation. Perhaps you only need to move to a newly built neighboring hall, or perhaps to a new location or even to another country. The specific layout of the logistics areas can also place special demands on the execution of the warehouse relocation. Our consultation therefore begins with an inspection of the current and planned locations and the recording of key data and special features. We then draw up an initial plan for the warehouse relocation and a cost calculation for our complete service from a single source.

You decide to what extent we support you with your warehouse relocation. Our service options range from individual activities to a complete service for warehouse relocation during ongoing operations. This starts right from the planning stage. We inspect the current and the new location and then develop a concept for implementation. If required, we can also support you in structuring the new storage capacities in preparation for the warehouse relocation. Any interim storage and the securing of transport chains are also topics that we deal with in terms of planning.

Our success factors for warehouse relocations

Individual planning and location analysis

We start every warehouse relocation with an inspection of both locations in order to create a customized concept that is tailored to your logistical and operational requirements.

Complete service even during operation

Whether partial or full service – we can handle your entire warehouse relocation on request, even while your business operations continue.

Professional transportation and assembly of shelving systems

Our experienced technicians take care of the safe dismantling, transportation and professional reassembly of all storage technology such as high-bay racking or heavy-duty systems.

Shelf inspection according to legal requirements

As part of the warehouse relocation, we also carry out rack inspections in accordance with DIN EN 15635 and DGUV – including an inspection report, recommendations for action and an inspection sticker.

Warehouse removals with professionals

A warehouse move can take on enormous complexity and require countless trades and specialists. It is crucial for a quick move without unplanned downtime that all steps and people involved are perfectly coordinated. This is where it pays off that we have the key skills in-house and can therefore offer our services even in the tightest of time frames. A central contact person as on-site project manager ensures perfect coordination of all parties involved and keeps you up to date at all times.

Challenges with warehouse relocations

Spatial planning and logistics

Warehouse relocations present companies with the daunting task of transporting their entire inventory of goods and equipment from one location to another. Space planning is crucial in this process. You need to ensure that the new warehouses not only offer sufficient space, but are also designed to optimize operational processes. Efficient space planning in the new warehouses is therefore essential. It enables quick access to goods, minimizes internal transport costs, and ensures clear organization.

The logistics of transportation is another challenge. It’s not just about getting goods from A to B. It’s also about moving them in the right order, at the right time and without interruptions. This requires careful coordination and planning

Safety and protection

During the move, your goods and equipment are exposed to potential risks. Therefore, it is of utmost importance to secure them throughout the process. Any damage or loss can have a significant financial impact and disrupt operations.

It is essential to take appropriate measures to prevent damage and loss. This can be achieved through the use of suitable packaging materials, the protection of sensitive goods and the careful handling of equipment.

Time management

Time is money, especially when it comes to business operations. A delayed warehouse move can lead to business disruption, which in turn can affect cash flow and customer satisfaction. Therefore, the move should be carried out as quickly and efficiently as possible.

The coordination of employees and external service providers plays a crucial role. Everyone needs to know exactly what their tasks are and when they need to complete them. This requires clear communication and detailed planning.

Want more insights? Take a look at Instagram!

Behind ZBV Fels is not only competence, but also

a strong team with heart, humor and a lot of energy.

You want to know what our everyday life looks like, which projects we are currently working on or simply take a look behind the scenes? Then our Instagram channel

is the right place for you!

FAQs

How does a warehouse move with ZBV Fels work?

We start with an inspection of the old and new location, record all the special features and create an individual relocation concept on this basis. Then – depending on your wishes – we take care of the entire process, from dismantling and transportation to reassembly of the shelving systems and storage of the goods.

Can warehouse relocations also be carried out during ongoing operations?

Yes, we specialize in organizing warehouse relocations in such a way that your day-to-day business continues as uninterrupted as possible. Through targeted planning and coordinated processes, we minimize interruptions and maintain your ability to deliver.

What happens to sensitive or particularly valuable stored goods?

Our trained employees pack sensitive goods professionally and ensure that even high-value or sensitive goods arrive safely at their new location. We use suitable packaging material and special transport solutions for this.

Does ZBV Fels also dismantle and reassemble shelving systems?

Yes, we dismantle and assemble all storage and shelving systems – from pallet racking and high-bay racking to mobile racking systems – including safe transportation and correct reassembly at the new location.

Does ZBV Fels also offer shelf inspections after the move?

Naturally. After the move, our certified rack inspectors carry out a complete rack inspection in accordance with DIN EN 15635 and DGUV Rule 108-007 – including an inspection report, recommendations for action and an official inspection sticker.